Agentic AI Hits the Warehouse Floor: From Demos to Daily Ops

On October 7, AutoScheduler released a free Warehouse Decision Agent, giving operators a low risk way to test agentic AI on real docks. This review covers deployment, governance, and a 90 day ROI plan.

The breakthrough: a free agent for real warehouse decisions

On October 7, AutoScheduler announced a free Warehouse Decision Agent aimed at coordinators who live inside labor rosters, dock schedules, and carrier calls. The pitch is practical: load the day’s schedules and constraints, and the agent proposes a plan, flags risk, runs quick what ifs, and drafts the communications that keep freight moving. The announcement matters because it removes the most common blocker to trying agentic tools in operations, which is the cost to experiment. You can see the details in the company’s press announcement on October 7, and the product is available on the AutoScheduler sign-up page.

For the last two years, many agent demos have lived in sanitized sandboxes. Real warehouses are different. They start early, run on handwritten notes at clipboards, and depend on brittle interfaces in the background. A tool that survives that environment must do more than chat. It has to interpret messy constraints, make decisions that respect safety and service, and keep people in the loop.

A free decision agent in the wild changes the adoption arc. Operations leaders can run it alongside existing warehouse, yard, and transportation systems to see if the agent produces a better sequence of moves with fewer touches. If it does, the next steps stop being theoretical. They become a playbook.

What agentic operations look like on the floor

Agentic operations are not a new software module. They are a way of working. Think of the agent as an extra coordinator that never sleeps, never gets flustered, and documents every call it makes.

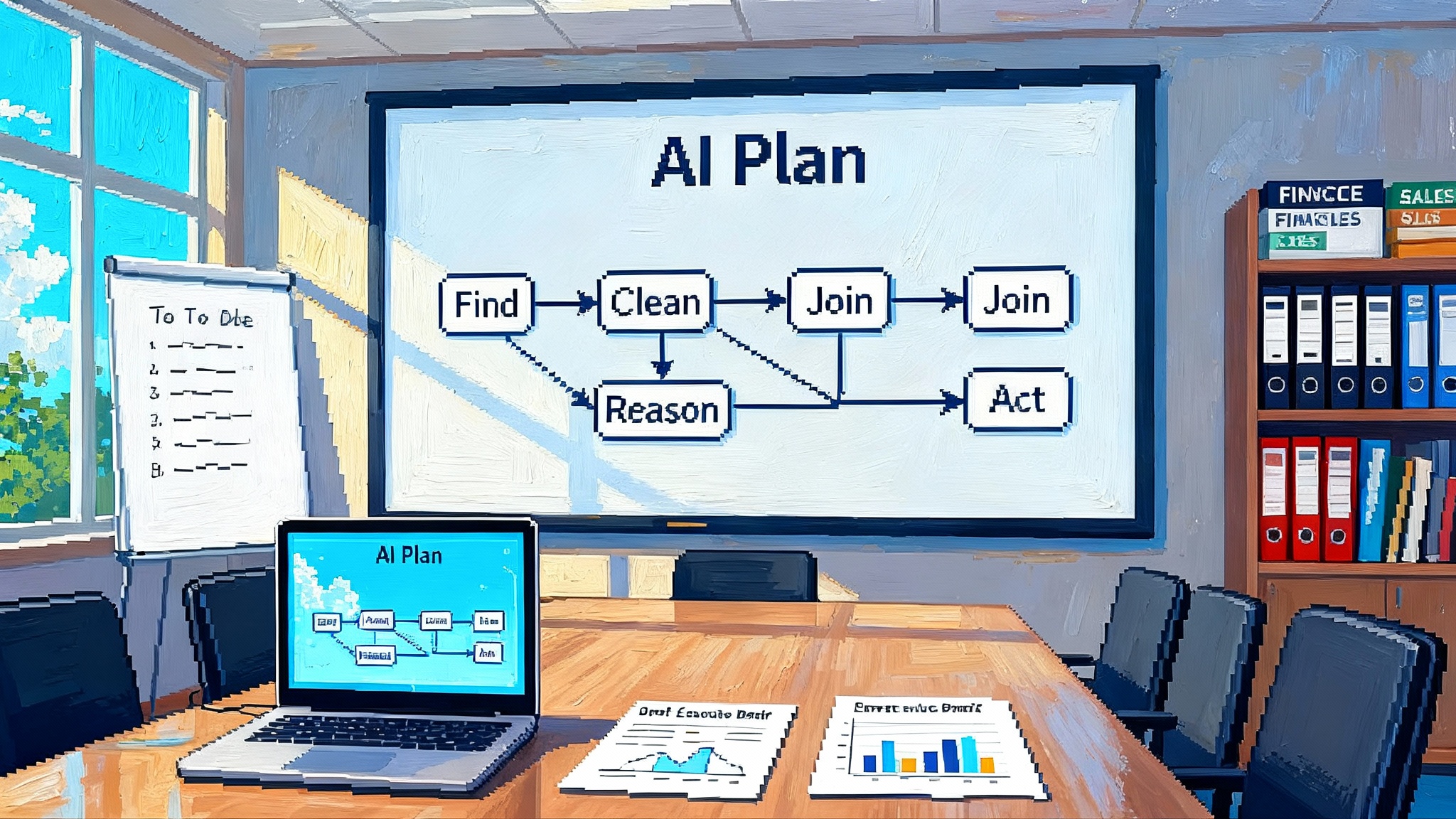

Turn shift plans into executable sequences

Agents start with the same inputs coordinators already use: labor assignments, door availability, inbound and outbound schedules, equipment status, and service priorities. From there, the agent produces a minute by minute sequence of moves that connect dock appointments, putaway, picks, replenishments, and trailer turns. In practice, that looks like this:

- Map the first two hours to quick wins: unload two high priority inbounds, crossdock three pallets to cover a late hot order, and delay a low risk nonconformance check until labor clears.

- Assign lift drivers to replenishments that unblock the next wave of picks, not just the nearest task.

- Suggest a short reshuffle of doors to avoid a deadhead from staging to shipping.

This is not magic. It is constraint solving plus a learned sense of which trade offs keep orders on time and workers productive.

Flag risk before it hits service

Great coordinators see trouble early. Agents can do the same at scale. Examples:

- Trailer dwell spikes at Door 12, which implies a bottleneck at the stretch wrapper. The agent prompts to reassign one laborer for forty minutes and adjusts the rest of the plan.

- A last minute priority order arrives with two missing SKUs. The agent warns that pick paths will collide at Aisle 17 and proposes a quick putaway to open flow.

- A carrier updates estimated time of arrival and slips departure by twenty minutes. The agent recommends swapping the next two doors to keep the high value outbound on schedule.

Run scenarios in seconds

Coordinators routinely ask what if questions. Agents should answer like this:

- If one department attends a stand up safety meeting, what does it do to departure times, and which trailer becomes the pacing item.

- If the sorter jams, what is the least disruptive picking plan for the next thirty minutes.

- If the hot order expands by four pallets, where does replenishment come from and who runs it without overtime.

The value is not just answers. It is consistency. The agent runs the same math every time, with the same constraints, so teams can trust the comparison.

Auto generate the comms that keep freight moving

A typical shift burns hours on updates. Agents can draft these so humans only approve and send:

- A crisp dock schedule with color coded risk notes for carrier partners.

- A handoff from first to second shift that lists what finished, what slipped, and what changes in the next three hours.

- A daily roll up with dock to stock time, trailer dwell, and top issues with owner and fix.

Done well, the agent is a communication turbine, not a decision black box.

The safeguards modern agents require

Operations will not adopt an agent that cannot prove it is safe. The guardrails are straightforward and non negotiable.

Approval gates

Start with read only recommendations, then add human approvals for categories of action. Examples:

- A supervisor must approve door reshuffles, overtime, or any pick plan change that touches a regulated item.

- The yard lead approves any live load pull that preempts a scheduled departure.

- The inventory manager approves cycle count deferrals beyond a set threshold.

Gate design turns into policy. It is easier to scale a policy than a tribal trick.

Rollbacks and safe stops

Every automated action must have a point of no regret. If an agent triggers a door swap and the carrier arrives early, a one click rollback should restore the prior plan with a timestamp. If the agent fails to get an acknowledgment from the warehouse management system, it should stop, alert, and revert the last change. Without safe stops, agents create silent chaos.

Audit trails and explainability

Agents must log the why, not just the what. If a door swap happens, the note should say the agent prioritized an on time departure for a premium customer and the alternative would have missed by twenty minutes, with a link to the comparison. If labor is reassigned, the log should cite the constraint that broke and the threshold that triggered the replan. These notes power continuous improvement and reduce guesswork in postmortems.

Least privilege and segregation of duties

Agents should only touch the tables, queues, and message topics they need. Use role based access, environment keys, and separate service accounts for planning versus execution. Map every action to a human owner in case an escalation chain is required.

The scorecard: KPIs that prove value

Leaders do not scale what they cannot measure. Four metrics tell the real story. Make them visible on day one.

1) Dock to stock time

- Definition: Average minutes from trailer arrival at the dock to inventory available to pick.

- Why it matters: Slow dock to stock traps working capital and starves picks.

- How agents help: Smoother sequencing, fewer long waits between unload and putaway, fewer replans during lunch and shift changes.

- How to measure: Start with a two week baseline by door and by item class, then publish a daily median and 90th percentile.

- Target: A fifteen to thirty percent reduction in the first quarter if the site has chronic congestion.

2) Trailer dwell

- Definition: Average hours between gate in and gate out.

- Why it matters: Fees, yard congestion, and downstream carrier impacts.

- How agents help: Dynamic door assignments when arrivals slip, automated nudges to clear empties, and faster recovery after disruptions.

- How to measure: Baseline by carrier and appointment type, then track weekly trends and count outliers above a set threshold.

3) On time departures

- Definition: Percentage of outbound loads that leave by scheduled time, with service levels weighted by customer priority.

- Why it matters: Prevents penalties and preserves network integrity.

- How agents help: Preemptive door and labor moves to protect critical cutoffs, real time reshuffles when the unexpected happens.

- How to measure: Daily report with variance buckets, plus a ladder chart that shows top three root causes by minutes lost.

4) Labor hours saved

- Definition: Hours of coordinator and floor time avoided per shift by adopting agent workflows.

- Why it matters: Frees skilled people to coach teams and clear systemic blockers.

- How agents help: Draft the plan, tee up decisions, and write communications.

- How to measure: Time motion sampling before and after rollout, plus self reported time saved against tasks such as email drafting and schedule edits. Publish a conservative number and tie it to overtime avoided.

AutoScheduler’s public materials point to gains such as double digit throughput and labor improvements. Treat those as directional until your own baseline confirms them.

A pragmatic rollout playbook

The fastest way to deploy an agent is to start narrow, prove value, and expand in rings.

Phase 1: Read only, zero risk

- Connect to the warehouse management system, yard system, and carrier feeds in a shadow environment.

- Ingest a live day’s schedules and constraints. Generate a recommended plan every fifteen minutes. No live writes.

- Publish comparisons: what the team did versus what the agent would have done, including service impact and labor minutes. Hold daily stand ups to review three deltas the team would actually adopt.

Success criteria: The agent’s plan would have protected at least one critical departure and saved at least one hour of coordinator time per shift without creating new risk.

Phase 2: Constrained actions with approvals

- Allow the agent to propose a short list of safe actions such as door swaps within a zone, pick path resequencing under a minute of travel difference, and proactive communications drafts to carriers and internal teams.

- Create approval gates tied to roles. Supervisors approve with one click inside the agent’s task feed.

- Add instant rollback for each action category.

Success criteria: A measurable improvement in on time departures and a visible reduction in trailer dwell outliers, with zero safety incidents and clear audit notes for every change.

Phase 3: Closed loop for stable slices

- Promote stable, high volume flows to full automation, such as repetitive crossdocks for a single retailer or first wave picks for a predictable product family.

- Keep humans in the loop for exceptions. The agent escalates when metrics slip or when confidence drops below a threshold.

- Expand scope by door banks, customer pools, or shift windows rather than by features.

Success criteria: Sustained improvements over four weeks, including dock to stock time and labor hours saved. Publish the before and after on a single page so executives and floor leaders see the change.

Change management that sticks

- Involve your best coordinators early. They know where plans fail and where rules need to bend. Their intuition should shape guardrails and playbooks.

- Train on failure modes. Run tabletop drills where the agent is wrong, the network hiccups, or a rollback is needed. Confidence grows when the team sees how the system behaves in bad weather.

- Use clear ownership. Every automated action has a named human owner. That simple step preserves accountability and gives people confidence to let the agent run.

- Communicate outcomes, not features. Report daily on the four KPIs, call out resolved bottlenecks, and share short video clips or screenshots of rollbacks and approvals in action.

Why warehouses are the first beachhead

Warehouses are rich in structured signals and short on decision capacity. They sit at the intersection of systems for inventory, yard, and transportation, and draw on data sources from telematics to labelers and sorters. That mix gives agents enough context to make useful recommendations without inventing new infrastructure.

There is also a culture of measurable outcomes. Docks and doors create natural scoreboards. If trailer dwell drops and departures improve, the win is obvious. If not, the program changes.

Finally, the work is coordination heavy. People lose hours each day to emails, schedule edits, and handoffs. That is exactly the kind of friction agents absorb. Once the pattern sticks in the warehouse, it can travel.

- Yard: Agents can triage live load pulls, balance empties, and sequence gate moves against dock reality.

- Port: Agents can reconcile berthing schedules with terminal capacity and truck flow, then inform partners when plans shift.

- Plant floor: Agents can align changeovers, material replenishment, and maintenance windows to hit takt time without starving assembly.

The same safeguards apply across these environments: approvals, rollbacks, and audit trails. The same scorecard does too, with local tweaks.

What success looks like in the first 90 days

Week 1 to 2: Baseline the four KPIs, install the agent read only, and validate data freshness and mapping. Capture three daily deltas where the agent’s plan would have helped.

Week 3 to 5: Move to constrained actions with approvals on a single shift. Publish a daily one pager that shows wins, issues, and the change log.

Week 6 to 8: Automate one stable slice end to end. Keep exceptions manual. Expand training to all coordinators and yard leads.

Week 9 to 12: Widen scope to a second door bank or customer pool. Lock in the governance rituals, including weekly reviews, a monthly safety check, and a quarterly postmortem on misses.

By the end of the quarter, the program should have a measurable impact on at least two of the four KPIs and a credible story about labor hours given back to the team. If that is not true, stop, simplify, and return to Phase 2 until stability returns.

Read more on accountable autonomy

If you want to compare approaches to oversight and measurement across domains, these pieces are helpful:

- How a consumer agent quantifies outcomes and traceability in email workflows: accountable autonomy in email.

- The engineering side of shipping agents quickly with fewer moving parts: compresses the agent stack.

- What a mature build test ship loop looks like when an agent owns the dev cycle: build, test, and ship autonomously.

The bottom line

A free warehouse decision agent that anyone can try is not a gimmick. It is a forcing function that will separate teams that experiment and measure from teams that wait and debate. Warehouses are the right first step because they combine clear data, repeatable work, and high cost of delay. The leaders who start with read only, graduate to constrained actions, and earn the right to close the loop will not just run tighter docks. They will set the pattern for yard, port, and plant agents that follow.

The point is not to automate everything. It is to automate the moments that matter, prove it with numbers, and keep people in charge of the why. AutoScheduler’s launch puts that future in reach today, not next budget cycle. Run it side by side with your live plan, set the guardrails, and score the results. If the numbers move, scale it. If they do not, you learned something for the cost of a pilot. That is how breakthroughs become routine work.